Humidity Control

Importance of humidity control

Indoor Environmental Quality (IEQ) has been a major talking point in the HVAC industry for the last 20 years but has never been more prevalent than the last 18 months. IEQ is driven by many factors including filtration, CO2 levels, Outdoor air intake, as well as the humidity within the space.

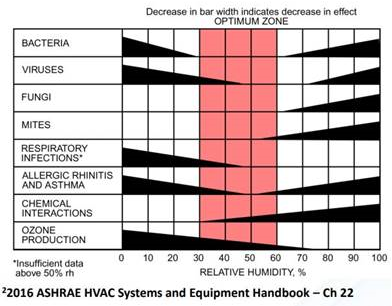

As shown in the ASHRAE Chart below, maintaining the humidity in a space can help to increase the air quality. Maintaining humidity within an HVAC system between 30-60% relative humidity is a balancing act that must consider system type, application, sequence, first cost, and life cycle cost.

Methods of humidity control in packaged rooftop units

There are varying approaches to humidity control within packaged rooftop systems. The most basic form of humidity control occurs during the standard cooling operation. The rooftop unit dehumidifies the air during the standard cooling operation but stops dehumidifying when the space temperature is met. Once the space temperature is met, the space humidity can and will start to increase. This of course leads to humidity conditions that may not be desirable. One method to improve upon this is to keep the cooling coil actively cooling for a longer period. This can be achieved by supplying units with additional cooling stages or even adding variable speed compressors.

A better option is to supply a hot gas reheat coil that is controlled through an on/off valve. The reheat coil adds enough heat to the leaving air so that unit avoids subcooling the space. This works well in many smaller applications. The package unit runs for longer periods which is enough to maintain humidity and temperature control. As the size and complexity of the application increases, the on/off control provides too little or too much reheat. In either case, the on/off valve control is no longer effective. For more complex environments and larger units, we recommend the use of modulating hot gas reheat to insure stable environmental control.

On the other end of the spectrum is the ability to humidify during the cold winter months. Due to the initial first cost, humidifiers have traditionally only been applied in critical applications like medical office buildings, and sensitive manufacturing spaces, etc. The majority of smaller packaged rooftop units do not have the internal space to install a humidifier. For these applications, it is common to find the solution through a duct-installed humidifier. Rooftop units that do allow for a humidifier to be installed internally can help the project construction team to save time and reduce integration issues through simplified installation and BAS coordination efforts.

As the importance of IEQ continues to further be discussed and documented, humidity control will continue to be adopted at an increasing rate.

Next Steps

Help customers select and take advantage of the TempMaster® packaged rooftop units available to help regulate humidity swings.

The rooftop platform offered by TempMaster® can provide hot gas reheat control from 3-150 tons. Units from 15-150 tons are provided with modulating hot gas reheat valve control.

To meet the more critical space requirements the Omni™ Premier line offers factory-installed humidifiers (25-50 tons). Omni™ Premier 60-80 ton humidifier options will be available for selection, pricing, and submitting this winter. Stay tuned for more information on the launch date coming soon.

Please reach out to your application support team for additional questions.